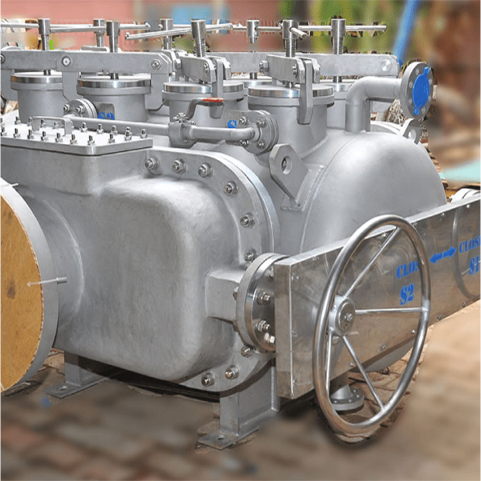

Automatic Strainers

Procedyne Automatic Scraper Strainer is a motorized unit designed for the continuous removal of suspended solids from intake, process and wastewater flows. These units can handle heavy solids loading with particles as small as 75 microns and as large as 150mm (6" stones). Our strainers have been installed on applications where backwash strainers have suffered premature clogging, such as black liquor, heavy oils, wax, unprotected river water intakes and boiler waste slurries.

Cleaning is accomplished by a spring-loaded blade and brush system managed by a fully automatic control system. The blades remove larger solids while the brush clean out the individual slots of the wedgewire filtration element, removing smaller particles.The spring-loaded mechanism maintains blade and brush contact with the screen at all times. A separate blowdown timer allows the accumulated solids to be expelled from the bottom of the strainer vessel where they are collected during the scraping cycle. Having a separate blowdown cycle allows our scraper strainer to use far less fluid for cleaning than competing backwash designs.

The Scraper strainers are available in sizes 2" through 36" in fabricated construction using carbon steel, stainless steel and assorted alloys. All strainer vessels are designed and built in general accordance with ANSI and ASME Sec. VIII, Div. 1. Nozzle arrangements can be offset (standard), in-line at the top and at the bottom of the vessel.

Typical Applications

Procedyne Automatic Scraper Strainers are used in nearly every industry to strain river, lake or seawater intakes for plant cooling water, fire protection and process requirements.

Process Industry - Protect heat exchangers, pumps, valves and water spray nozzles.

Power Industry - Protect heat exchangers, pump seal water, boiler wash water nozzles.

Pulp & Paper - White water and black liquor filtration.

Wastewater Treatment - Straining secondary effluent to protect spray nozzles and provide plant service water.

Metal and Mining Industries - Provide clean water for quenching, de-scaling, blast furnace cooling.