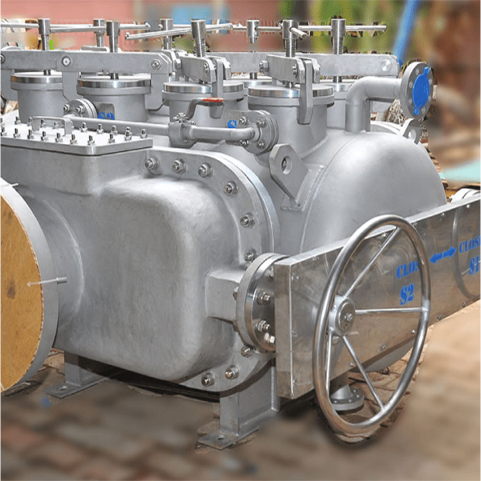

Basket

Strainers

Basket strainers have a greater holding capacity than the Y-strainers. They also have less pressure drop. Hence, these are ideal for liquid applications where debris collection is huge and frequent.

Basket Strainers feature top removal of the screen. The screen is in the form of a basket, with a lifting handle, so that all particulate captured and retained by the screen can be easily removed for disposal. They are intended for applications where large amounts of solids particulate are expected and where the clean-out will be frequent. For easily flushable solids, a modified cone bottom basket can be tilted with automatic or manual blow-down through drain port. This will allow clean-out without removal of the screen, and without interrupting the flow process.

Our basket strainer range is available in size from 3/8" – 24" with Threaded, Socket Weld or Flanged End Connections. Pressure ratings are ANSI 125-600#. Standard body materials offered are Cast Iron, Ductile Iron, Cast Steel, Stainless Steel, Chrome-Moly and Bronze. Various Perforations, Mesh or Perforation Mesh combinations baskets are available to meet your process requirements.

Procedyne Basket Strainers can be equipped with Bolted Covers, Hinged Covers, Clamped Covers, a Davit Lifting Device or other Lifting Device to make removal of large heavy covers safe and efficient. Widespread list of options are available. Basket Strainers are in stock at Procedyne Engineers ensuring prompt delivery of your order.

Video: 24" Basket Strainer 150# in Ni-Aluminium Bronze under machining